FAG History

Joseph-Otto Bobst founded FAG* SA Lausanne in 1937 and introduced the American Form-Test method to Europe. (*Fournitures pour les Arts Graphiques = Supplies for the Graphic Arts)

Early years

In 1937, the year in which the company was established, the European printing trade was dominated by letterpress printing techniques and predominantly had the structure of a craftman’s trade. Coming from a family with a history rooted in the print production, Joseph-Otto Bobst Jr., son of Joseph-Otto Bobst Sr., the founder of Bobst S.A., founded Furniture pour les Arts Graphiques — FAG. Drawing on his experience gained in America, Joseph-Otto Bobst Jr., the older brother of Henri Bobst, turned his attention to the challenges of rationalisation within in letterpress printing. Henri Bobst was responsible for the successful development of Bobst S.A. through innovations in printing and packaging machinery, also based in Lausanne. Joseph-Otto Jr. focused mainly on forme setup, proofreading and corrections, make-ready, and the overall goal of reducing the costly hours on production presses. He established himself as an independent businessman and founded FAG, giving it the legal form of a limited company.

As a first step, the new company acquired the rights and distribution agreements for American printing-related products or services—mainly for block leveling and makeready. However, it made a name for itself through the ambitious and consequential development of the FAG Form-Test method, probably inspired by US competitors with similar motivations, such as Vandercook or Hacker. This method rapidly became established in leading printing companies and is a patented trademark. The aim of the FAG Form-Test was to prepare a printing forme as perfectly as possible outside the production press, including makeready and final proofing, in order to reduce non-productive press time on the expensive production presses. In this way, FAG became synonymous with rationalisation and more efficient printing.

First production years

After the Second World War, operating as a sales organisation and initially without its own manufacturing facilities, FAG took advantage of the Marshall Plan that supported the process of importing American machinery, in particular Vandercook cylinder proof presses, to Europe. They also built up FAG agencies in Germany, Italy, France and England. With a network of exclusive agents in Europe and overseas, as well as competent consultacy and reliable service, FAG acquired a reputation as a respected service company throughout the printing industry. In doing so, the company made an important contribution to raising standards of quality and to the industrialisation.

In 1946, FAG started to build their first printing presses in Germany (Singen) and mechanized tools for make-ready in France (Lyon, Annecy).

In the 1950s, FAG Form-Test saw the need to adapt American equipment to the new European requirements. At the same time, the company needed to keep up with the growing industry in Germany. The recognition by the French government of FAG as a national export company proved to be a stroke of good fortune. Among other benefits, it enabled FAG to sell and put into operation the first Klimsch reproduction cameras in Paris.

During this period, FAG also expanded their business to Yugoslawia and Eastern Europe

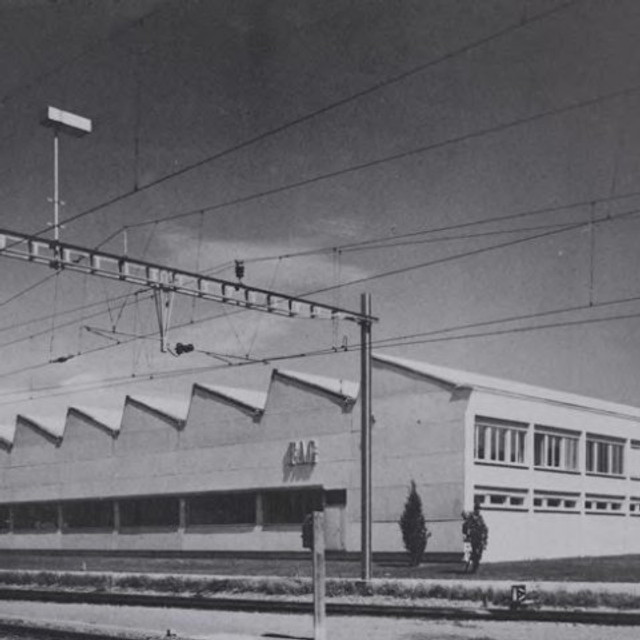

Production facilities in Avenches, Switzerland

FAG cylinder proof presses, precision trim saws, block casters, specialized extension quoins, plate drills, type height and slug gauges, register galleys, block levelers and many other tools and machines for accelerating the prepress process were selling well but at that point were still manufactured at several facilities abroad. For this reason, FAG built its own manufacturing facilities in the beginning of the 1960s in Avenches (CH) just 50km from Lausanne. The site was located on archaeologically sensitive ground, which delayed construction somewhat.

In 1962, the first part of the plant was put into operation. By 1964, FAG already doubled the capacity of that building—which they initially had planned for in long term. From that time on, they manufactured all their products for the FAG Form-Test-Method exclusively in their own facilities in Avenches.

During this same period, when FAG started to produce their most famous letterpress proof presses: the FAG Control and later the FAG Swissproof, which were exported to all five continents. FAG letterpress proof presses became known for their «Swiss» precision, sturdy construction, reliability and smooth working. The proof presses were built with massive construction and great weight to achieve the same strength and register accuracy as the best production presses from that period. They were built to last for a lifetime—or longer—and you are lucky if, once moved, you would never have to move them again …

It is noteworthy that other companies, such as the US competitor and market leader Vandercook, from the 1960s onward, made little effort to develop new letterpress proof press models. Instead, they gradually shifted their focus to refurbishing existing machines, in response to the transition from letterpress to offset printing. FAG in Switzerland, however, only truly began only really started in 1962, with a new manufacturing facility, producing proof presses using state-of-the-art methods.

For Drupa* 1970 (Fachmesse für Druck und Papier*, an important prininting fair) in Düsseldorf, Germany, FAG overhauled and updated its entire model line of proof presses and introduced the FAG Swissproof 40 and Swissproof 52. Consequently, the development of letterpress proof presses FAG occurred relatively late, and as a result, was technically superior to many of its competitors.

Towards the new needs of the offset industry

The commercial replacement of the letterpress process by offset printing, beginning in the early 1970s and continuing into the mid 1980s, led to well-known structural changes within the printing industry and fundamentally altered the technical requirements for proof presses.

In 1972, FAG delivered its first flatbed offset proof press the ‹7654› from Avenches. The transition from the production of letterpress proof presses to the offset proof presses was completely smoothly, and FAG seemed be highly agile in reacting to the new needs of the industry.

For Drupa 1977, FAG presented the next milestone in its history: the FAG OP-104, a flatbed offset proof press in the printing size 72×104cm. It was the world’s first offset-proofpress with interchangeable inking units, which significantly reduced wash-up time between color changes. Until the year 2000, approximately 1’500 OP-104 units were delivered worldwide from the manufactory in Avenches.

In 1985, FAG developed its last proof pressm odel to be produced in Avenches. The Speedproof 4C, a 71×104cm four color rotary proof press, which often was modified to a production. This press produced four color proofs wet-on-wet with four inking systems around one cylinder.

During the years of offset proof press production, letterpress proof press production slowly faded from the mid 1970s onward and was largely replaced by offset proof press production. In the mid 1980s, letterpress proof press production mostly came to a halt. According to an interview with Mr. Orville at FAG conducted in 2011, the last batch of 15 FAG Control 405 letterpress proof presses was ordered by a distributor in Russia and delivered in 1991.

Around the year 2000, FAG started a cooperation to build the FAG-Korrex 2000, a new flatbed offset proof press, which was manufactured by the Max Simmel facilities in Germany. The production of offset proof presses in Avenches subsequently came to a halt. The manufacturing facility was cleared out and used by Bobst S.A. as a die-cutting manufacturing facility until 2009. The building was cleared and sold around 2010.

From ‹Form-Test-Method› to ‹Quality Control›

Simultaneously with their developments in offset proofing since the early 1970s, and still guided by the vision of the Form-Test-Method (nowadays more broadly referred to as ‹quality control›) FAG began developing densitometers and remains active today in their production for almost any part of the printing industry.

As offset proofing can now largely be simulated with inkjet technology and is therefore only required in specialized areas of commercial printing—such as security printing, currency production, metal printing, and other packaging applications— has shifted the production of its new quality control tools (of which only a small part is still actually proofing-systems) to specialized manufacturers abroad.

FAG proof presses today

Between 1962 and 1991 about 2000 letterpress cylinder proof presses were built in Avenches. In 2009, the manufacturing facility in Avenches was cleared out and closed down. New offset proof presses (FAG-Korrex 2000) are now built in Germany. Full revisions of offset and letterpress proof presses are coordinated from Lausanne and are made in Payerne, Switzerland. The spare parts archive, production sheets of all presses ever manufactured in Avenches, as well as all blueprints and technical drawings were transferred to the FAG headquarters in Lausanne.

FAG still has a huge spare parts archive and all blueprints to produce every part of every press. They will gladly assist with any technical issues. They still sell their parts for the same prices as they used to be back then—but they should not be expected to be inexpensive just because they are old. FAG letterpress proof presses are high quality precision equipment were already expensive when first produced, and their parts therefore continue to retain their value today.