405 × 580 mm

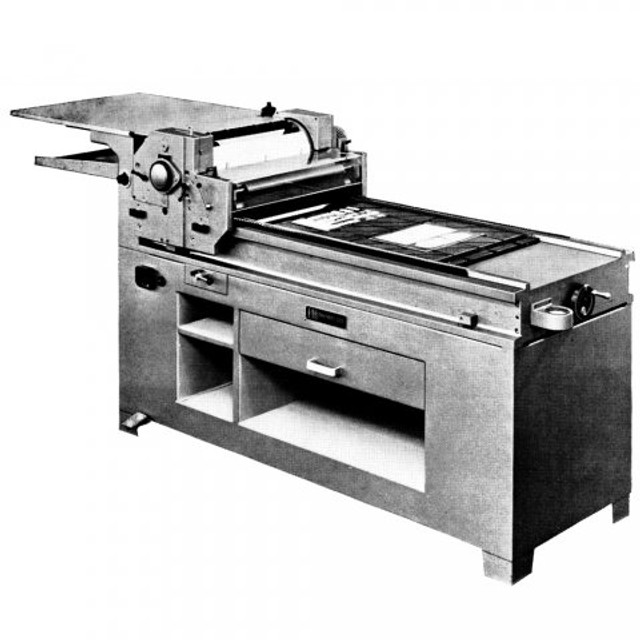

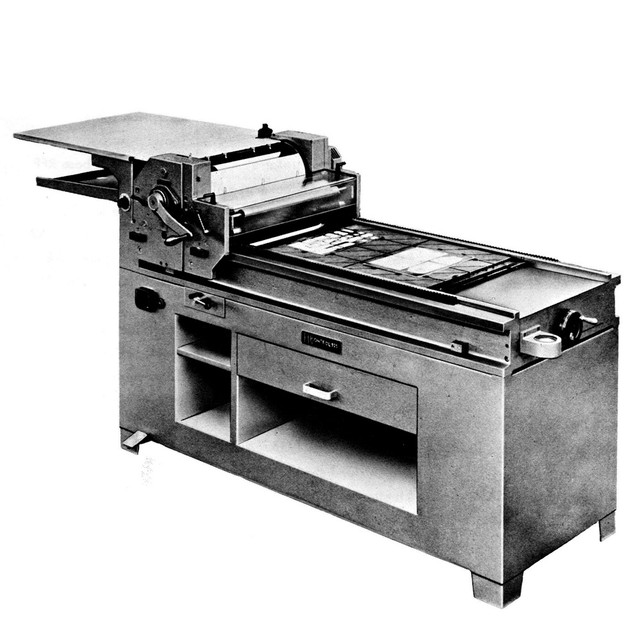

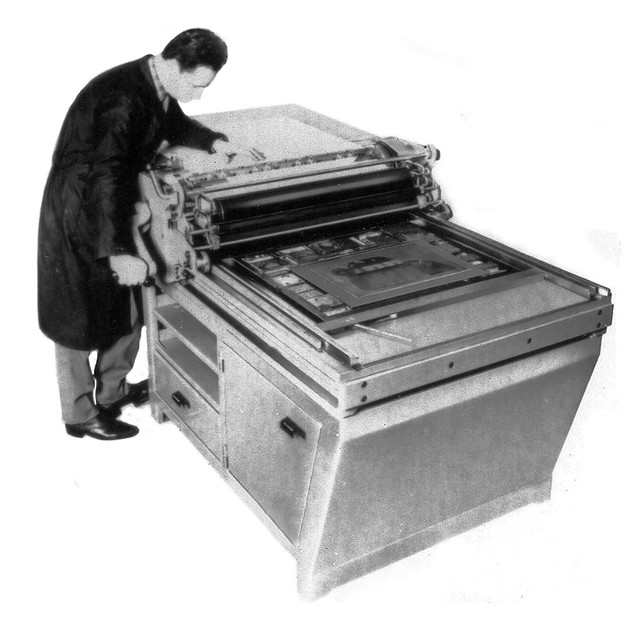

FAG Control 405

‹Presses with fixed or micro adjustable beds, hand or power operated with stepless speed adjustment. Special equipment for photoengravers, repro services, lay out, composing rooms and laboratories of ink and paper manufactures.› FAG Control 405/525 order sheet, circa 1968

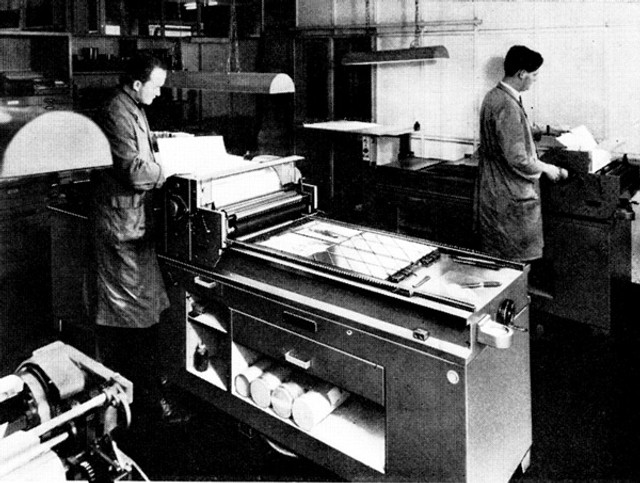

The FAG Control 405, together with the later simplified model FAG Swissproof 40, were the most common FAG letterpress proof presses.

These small-format presses were built to deliver very fast and highly precise color proofs. Equipped with a power-driven cylinder (MC or MVA), they can produce up to 300 proofs per hour.

Outstanding features on Test Press FAG Control

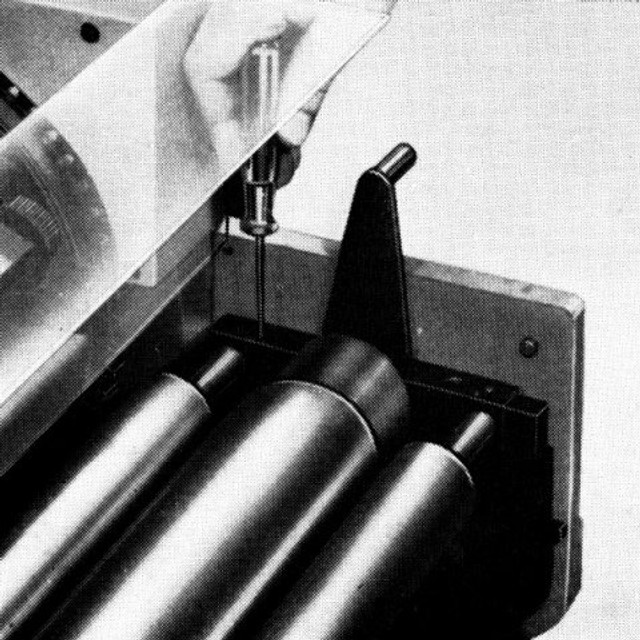

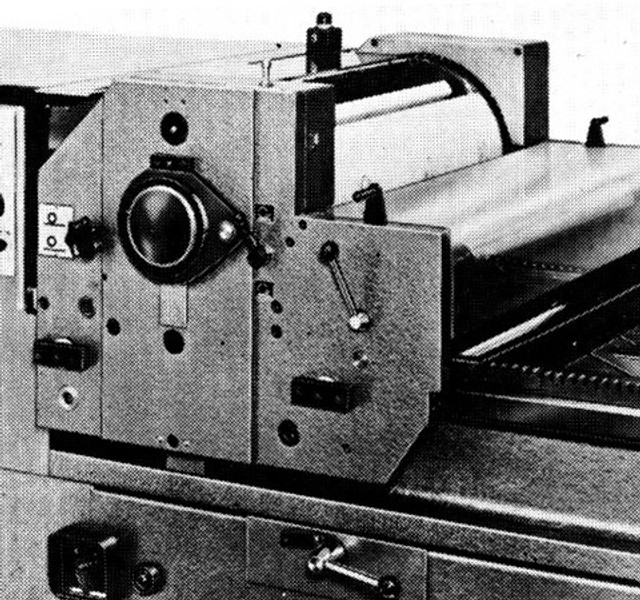

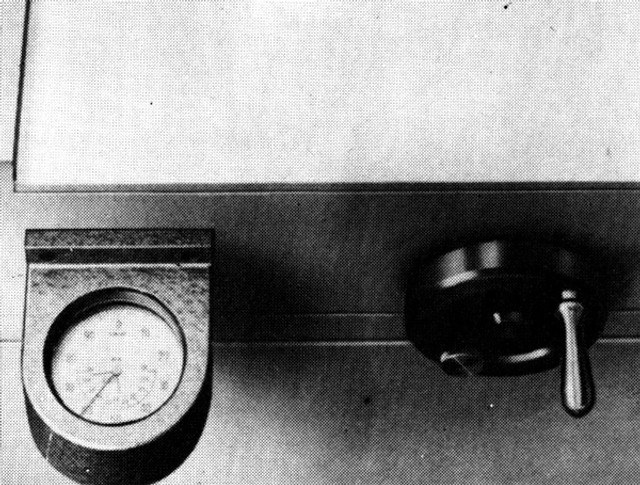

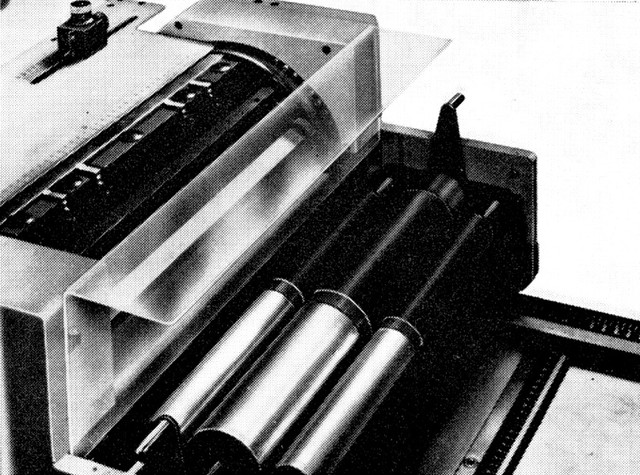

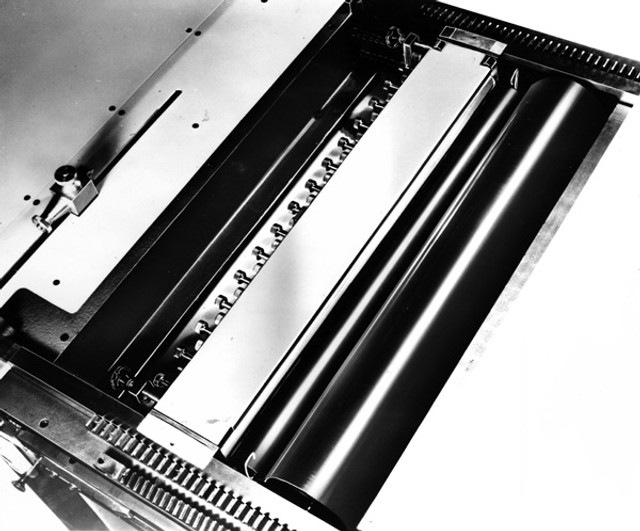

Swing-away ink distribution provides free acess to inking rollers. Inking rollers are mounted on ball bearings. Height adjustment with one single screw. one complete set of inking rollers can be stored on the machine, ready for immediate use. Wedge-type adjustable bed.Bed height adjustment and effective printing height are clearly indicated on a large dial with 1/1000mm (0.0001″) divisions.

Cylinder carriage with ball bearings for precise lateral guidance. Power drive with electronic, stepless speed adjustment. Two-speed power inking: accelerated speed for wash-up and ink distribution, normal speed for printing.

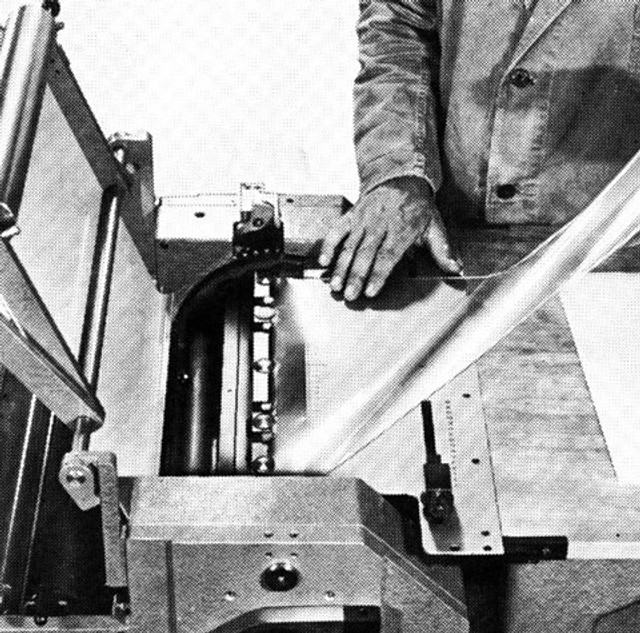

Feed board with swing-away panel serving as a safety device, plus additional safety features for power-driven presses.

Bearer surfaces protected with interchangeable steel bands (available on other later FAG Control models).

Quickspecs

Pressbed size

Paper size

400 × 580 mm

Form size

400 × 560 mm

Press size (l/w/h)

2.3 × 0.86 × 1.2 m

Press weight

Fixed bed: 550kg / adjustable bed: 650kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

Optional equipment

AR / Automatic cylinder return with time adjuster for sheet delivery. (This setting is advisable for orders of Cylinder drive MC.)

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

CP / Special attachment with steel tension roller and .040 inch offset blanket for transparency proofs.

DAS / Split steel rider unit for 2 colour work.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

MC / Cylinder drive with motor and FIXED SPEED SETTING.

MR / Micro adjustable bed movement with clock indicating accurate height in fractions of thousands of an inch. Height is measured directly off table.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

SAF / PMA / Automatic sheet delivery combined with pre lay device for automatic feeding of sheets. Automatic gripper opening at the feed board.

SAM / Safety device for motor-driven machine.

SR / Precision chase

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

TC / Centre side lay for 2 colour work

Number of presses built

~1200

Serial numbers

02.xx.xxx

Built in factory

Avenches, Switzerland

First / last press delivered

1962 / 1991

Price range

20'000 – 30'000CHF

Known presses still in use

FAG Control 525

‹The FAG Control 525 offers those few extra centimetres—or inches—that are often needed.› FAG Control 405/525 order sheet, circa 1968

The FAG Control 525 and FAG Swissproof 52 are medium-sized proof presses built in Avenches, Switzerland. The FAG Control 525 is a precision test press designed for high-quality proofs produced by printers, for fine repro proofs from hot-metal composition, and for single- and multi-colour proofs produced by process engravers.

Remove the bottleneck in the proving section

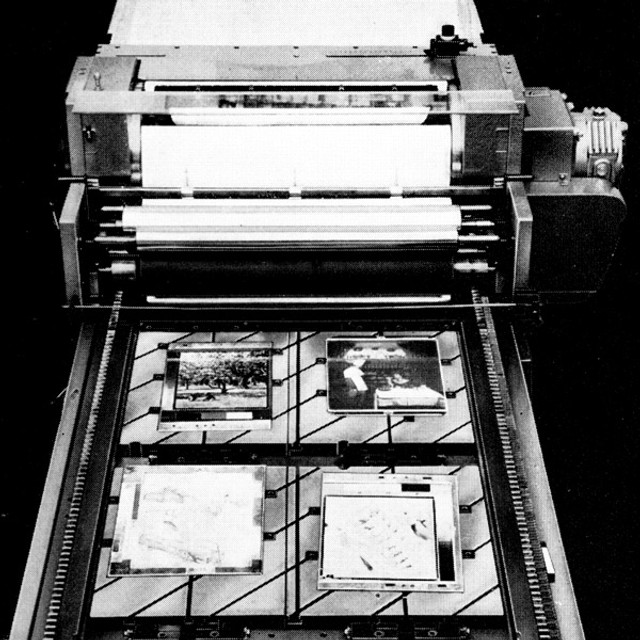

Produce more color proofs in less time. Equipped with a power-driven cylinder (MC or MVA), these presses could run up to 300 proofs per hour. A universal register plate allows locking up and printing 4 or 2 plates of the same color from 4 or 2 different colour sets, with easy changeover to print full-size plates on the same base.

As with the FAG Control 405, a wide range of standard and optional equipment was available for the FAG Control 525.

Quickspecs

Pressbed size

525 × 720 mm

Paper size

520 × 720 mm

Form size

520 × 720 mm

Press size (l/w/h)

2.7 × 0.97 × 1.1 m

Press weight

Fixed bed: 900kg / adjustable bed: 1200kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

Optional equipment

AR / Automatic cylinder return with time adjuster for sheet delivery. (This setting is advisable for orders of Cylinder drive MC.)

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

CP / Special attachment with steel tension roller and .040 inch offset blanket for transparency proofs.

DAS / Split steel rider unit for 2 colour work.

DCC / Cutting device at the end of the automatic sheet delivery for cutting sheets into 3 slips with automatic assembly of the slips.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

MC / Cylinder drive with motor and FIXED SPEED SETTING.

MR / Micro adjustable bed movement with clock indicating accurate height in fractions of thousands of an inch. Height is measured directly off table.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

SAF / PMA / Automatic sheet delivery combined with pre lay device for automatic feeding of sheets. Automatic gripper opening at the feed board.

SAM / Safety device for motor-driven machine.

SR / Precision chase

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

TC / Centre side lay for 2 colour work

Number of presses built

400–500

Serial numbers

03.xx.xxx

Built in factory

Avenches, Switzerland

First / last press delivered

1962 / 1986

Price range

30'000 – 40'000CHF

Known presses still in use

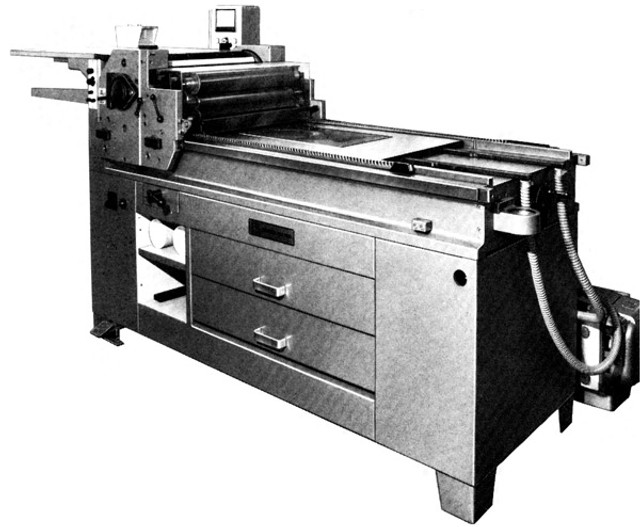

FAG Control 525-MRS

‹The FAG Control 525-MRS is the perfect proofpress for all process engravers who want to make sure that all values programmed at the stage of colour selection with the help of considerable technical equipment are not lost when printing proofs on paper.› FAG Product Catalog, around 1972

The FAG Control 525-MRS was a very late and high technisized letterpress proofpress that was perfect for very exact multi-coloured proofs. The MRS update was the newest update for Drupa 1972 for the Control model line. With the MRS model, FAG created a very high class press as a contrast to the two new Models Swiss Proof 40 and Swiss Proof 52, also presented at Drupa 1972.

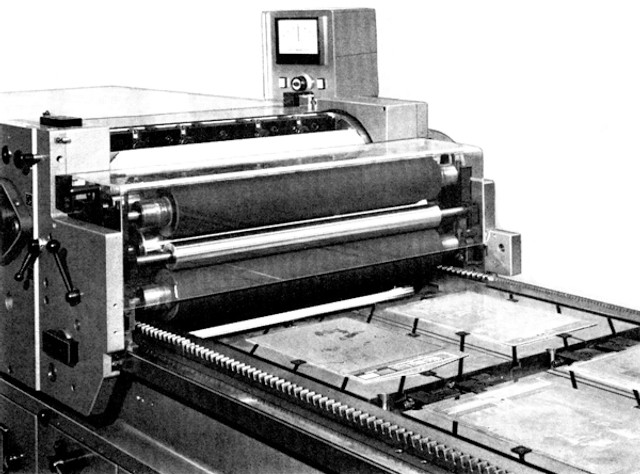

Developped for Drupa 1972

This press has been the latest development of the FAG Control 525 for Drupa 1972. The new inking system "S" with two extra rollers for complete regularity of ink transfer from rollers to printing plates over the full length of proof could be equipped with the FAG Densicolor, an electronic measuring device for the thickness of ink films. In this combination, the inking system would deliver a very constant and exact inking of the form/plate.

Quickspecs

Pressbed size

525 × 720 mm

Paper size

520 × 720 mm

Form size

520 × 720 mm

Press size (l/w/h)

2.7 × 1 × 1.25 m

Press weight

1200kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

MR / Micro adjustable bed movement with clock indicating accurate height in fractions of thousands of an inch. Height is measured directly off table.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

Optional equipment

AR / Automatic cylinder return with time adjuster for sheet delivery. (This setting is advisable for orders of Cylinder drive MC.)

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

CP / Special attachment with steel tension roller and .040 inch offset blanket for transparency proofs.

DAS / Split steel rider unit for 2 colour work.

DC / FAG DENSICOLOR – electronic control of the ink film.

DCC / Cutting device at the end of the automatic sheet delivery for cutting sheets into 3 slips with automatic assembly of the slips.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

PLA / VAK / Vacuum base with possibility to use up to 8 section for vacuum concentration. Especially for thin Nyloprint and Dycril plates. Vacuum pump capacity 60m3/h with all necessary parts for connection to PLA vacuum base.

RAF / Automatic sheet return to feed board.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

SAF / PMA / Automatic sheet delivery combined with pre lay device for automatic feeding of sheets. Automatic gripper opening at the feed board.

SAM / Safety device for motor-driven machine.

SR / Precision chase

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

TC / Centre side lay for 2 colour work

Number of presses built

50–100

Serial numbers

03.xx.xxx

Built in factory

Avenches, Switzerland

First / last press delivered

1972 / 1986

Price range

35'000–55'000CHF

Known presses still in use

FAG Control 800

‹The FAG Control 800 was an early handcranked press manufactured in Singen, Germany. The press has probably been developed in the early 1950ies and has been the first of the ‹Control› series.›

Since it is a very early press, unfortunately not much catalog information about it survived.

Quickspecs

Pressbed size

815 × 828 mm

Paper size

815 × 541 mm

Form size

770 × 541 mm

Press size (l/w/h)

2.035 × 1.3 × 1.045 m

Press weight

~1000kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

Optional equipment

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

Built in factory

Singen, Germany

First / last press delivered

? / 1958

Known presses still in use

FAG Control 835

‹The newly designed proof and test press with same gripper and print line as the production presses of similar size. A machine which allows proofing and testing of formes and plates und working conditions, in particular — printing strength, print line and ink coverage. The ideal proof press for any printing plant, photo-engraver and platemaker. ›Quotation sheet, late 1950ies.

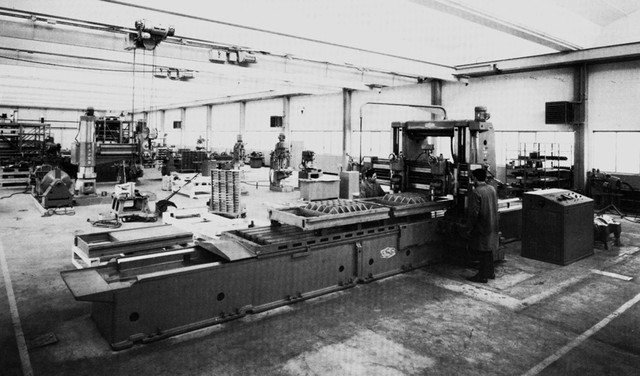

Moving production from Singen to Avenches

This press has been manufactured in Singen, Germany until 1962. Then they switched the production manufactury from Singen to the brand new manufactury in Avenches, Switzerland in 1962. Only after 2 years of manufacturing the FAG Contol 835 in Avenches, they developed it in to the slightly bigger FAG Control 839.

Quickspecs

Pressbed size

835 × 680 mm

Paper size

835 × 680 mm

Form size

825 × 640 mm

Press size (l/w/h)

2.5 × 1.5 × 1.2 m

Press weight

1700kg

Standard equipment

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

Optional equipment

AFR / Automatic frisket.

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

DAS / Split steel rider unit for 2 colour work.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

TC / Centre side lay for 2 colour work

TRM / Additional side-lay on the left. Adjusting device on the control panel.

Known presses still in use

FAG Control 839

‹The world known manufacturers of production presses have recently increased bed sizes. The size of the FAG Control 839 is well within these increased capacities.› FAG Digest Magazine, 1/1966

1964–1968

The FAG Control 839 was an optimized version of the FAG Control 835. Since the FAG Control 835 has been developped in Singen, Germany and been produced in Singen first and later in Avenches, Switzerland, it had to be optimized for production in Avenches. Thats when they developped the FAG Control 839 in 1964 in Avenches. It was actually almost the same press in almost the same size as the C-835, just with some little adjustements for production. Already in 1968, FAG made the next developement step to the FAG Control 900, which was a complete new press...

Quickspecs

Pressbed size

839 × 680 mm

Paper size

839 × 680 mm

Form size

839 × 640 mm

Press size (l/w/h)

2.5 × 1.5 × 1.2 m

Standard equipment

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

Optional equipment

AFR / Automatic frisket.

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

DAS / Split steel rider unit for 2 colour work.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

TC / Centre side lay for 2 colour work

TRM / Additional side-lay on the left. Adjusting device on the control panel.

Built in factory

Avenches, Switzerland

First / last press delivered

1964 / 1968

Known presses still in use

Download files

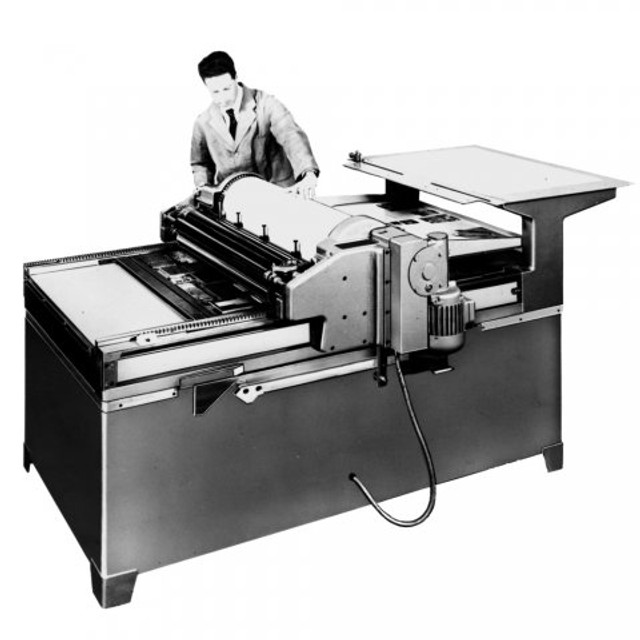

FAG Control 900

‹Production Presses with only tested formes ready to print. This is the goal you want to reach. In this case you certainly need a Test and Revision Press with the best possible printing strength and register. (…) The Testpress FAG Control 900 has been thoroughly checked by printers under the most difficult conditions, and the results achieved were excellent on all points. › FAG Product Catalog, around 1968

The FAG Control 900 was the biggest letterpress proofpress FAG ever built. Its antecessors were the FAG Control 800, FAG Control 835 and the FAG Control 839 (As with all models, the number means the width of the pressbed) which were slightly smaller models. With every revised version FAG sized this press a bit up until in 1968 they built the Control 900 for the first time.

Heavyweight proofpress

For its size, the FAG Control 900 only came with power driven cylinder and only with a fixed pressbed. Another very important difference to the smaller models was that with the FAG Control 900 will print in landscape format – means that the grippers will hold the sheet on the longer (!) side.

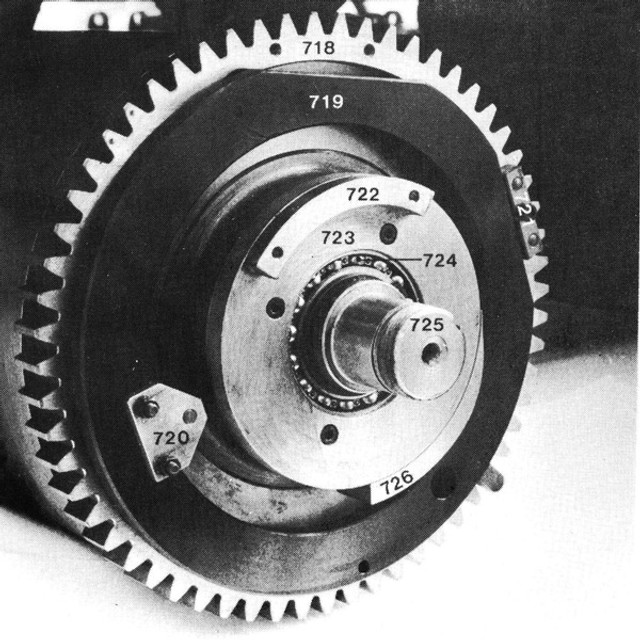

This press was not only the biggest letterpress proofpress FAG ever built, but also the heaviest. The heavy machine bed (about 1'000kg) with the underside stress is designed to guarantee maximum printing strength. This bed, together with the heavy closed printing cylinder (about 500kg) and full length axle which will not deflect under the heaviest pressure, form an association of lasting accuracy and precision.

Quickspecs

Pressbed size

900 × 680 mm

Paper size

895 × 680 mm

Form size

894 × 640 mm

Press size (l/w/h)

2.45 × 1.6 × 1.2 m

Press weight

2000kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

Optional equipment

BAT / Special pitch line bars to suit all machine chases.

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

ES / Ink Duct with distributor

PLA / VAK / Vacuum base with possibility to use up to 8 section for vacuum concentration. Especially for thin Nyloprint and Dycril plates. Vacuum pump capacity 60m3/h with all necessary parts for connection to PLA vacuum base.

SAF / PMA / Automatic sheet delivery combined with pre lay device for automatic feeding of sheets. Automatic gripper opening at the feed board.

SAM / Safety device for motor-driven machine.

TRM / Additional side-lay on the left. Adjusting device on the control panel.

Number of presses built

70–80

Serial numbers

05.xx.xxx

Built in factory

Avenches, CH

First / last press delivered

1968 / 1986

Price range

33'000 – 55'000CHF (~1968)

Known presses still in use