525 × 720 mm

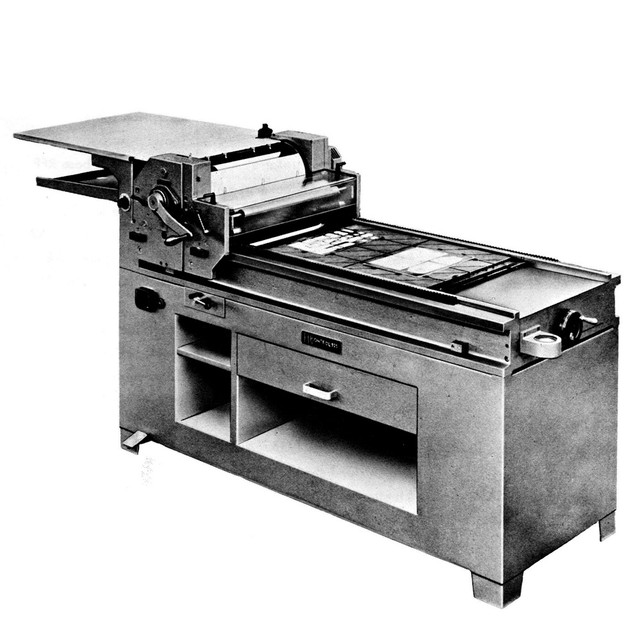

FAG Control 525

‹The FAG Control 525 offers those few extra centimetres—or inches—that are often needed.› FAG Control 405/525 order sheet, circa 1968

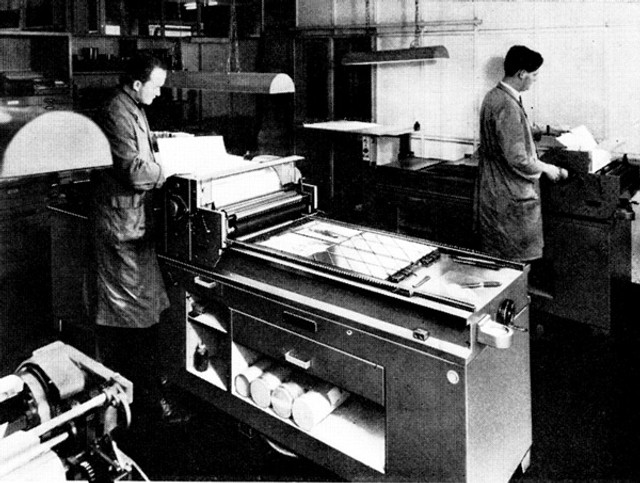

The FAG Control 525 and FAG Swissproof 52 are medium-sized proof presses built in Avenches, Switzerland. The FAG Control 525 is a precision test press designed for high-quality proofs produced by printers, for fine repro proofs from hot-metal composition, and for single- and multi-colour proofs produced by process engravers.

Remove the bottleneck in the proving section

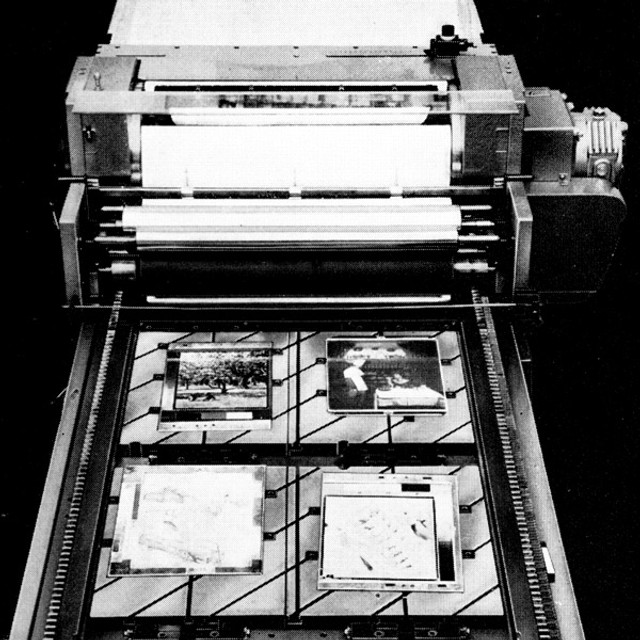

Produce more color proofs in less time. Equipped with a power-driven cylinder (MC or MVA), these presses could run up to 300 proofs per hour. A universal register plate allows locking up and printing 4 or 2 plates of the same color from 4 or 2 different colour sets, with easy changeover to print full-size plates on the same base.

As with the FAG Control 405, a wide range of standard and optional equipment was available for the FAG Control 525.

Quickspecs

Pressbed size

Paper size

520 × 720 mm

Form size

520 × 720 mm

Press size (l/w/h)

2.7 × 0.97 × 1.1 m

Press weight

Fixed bed: 900kg / adjustable bed: 1200kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

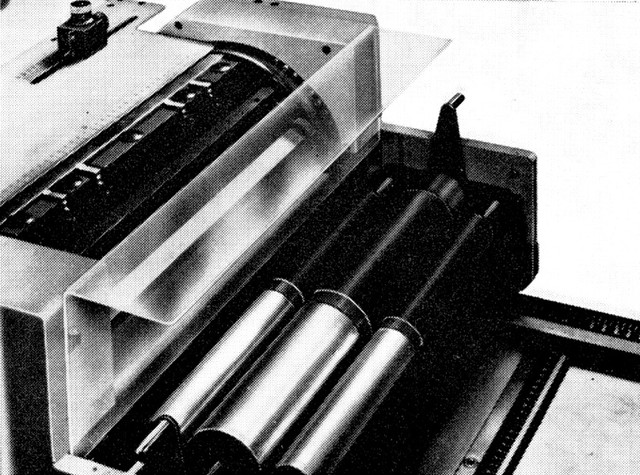

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

Optional equipment

AR / Automatic cylinder return with time adjuster for sheet delivery. (This setting is advisable for orders of Cylinder drive MC.)

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

CP / Special attachment with steel tension roller and .040 inch offset blanket for transparency proofs.

DAS / Split steel rider unit for 2 colour work.

DCC / Cutting device at the end of the automatic sheet delivery for cutting sheets into 3 slips with automatic assembly of the slips.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

MC / Cylinder drive with motor and FIXED SPEED SETTING.

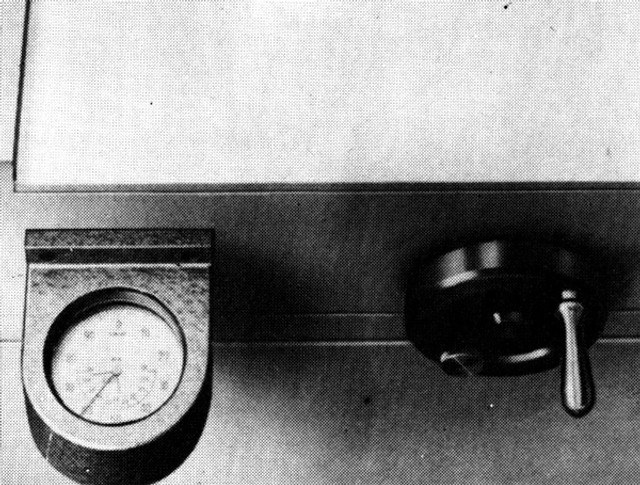

MR / Micro adjustable bed movement with clock indicating accurate height in fractions of thousands of an inch. Height is measured directly off table.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

SAF / PMA / Automatic sheet delivery combined with pre lay device for automatic feeding of sheets. Automatic gripper opening at the feed board.

SAM / Safety device for motor-driven machine.

SR / Precision chase

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

TC / Centre side lay for 2 colour work

Number of presses built

400–500

Serial numbers

03.xx.xxx

Built in factory

Avenches, Switzerland

First / last press delivered

1962 / 1986

Price range

30'000 – 40'000CHF

Known presses still in use