405 × 580 mm

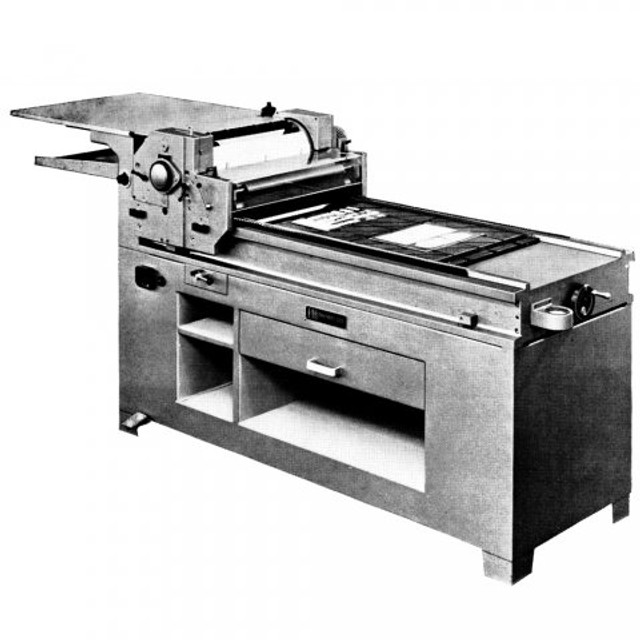

FAG Control 405

‹Presses with fixed or micro adjustable beds, hand or power operated with stepless speed adjustment. Special equipment for photoengravers, repro services, lay out, composing rooms and laboratories of ink and paper manufactures.› FAG Control 405/525 order sheet, circa 1968

The FAG Control 405, together with the later simplified model FAG Swissproof 40, were the most common FAG letterpress proof presses.

These small-format presses were built to deliver very fast and highly precise color proofs. Equipped with a power-driven cylinder (MC or MVA), they can produce up to 300 proofs per hour.

Outstanding features on Test Press FAG Control

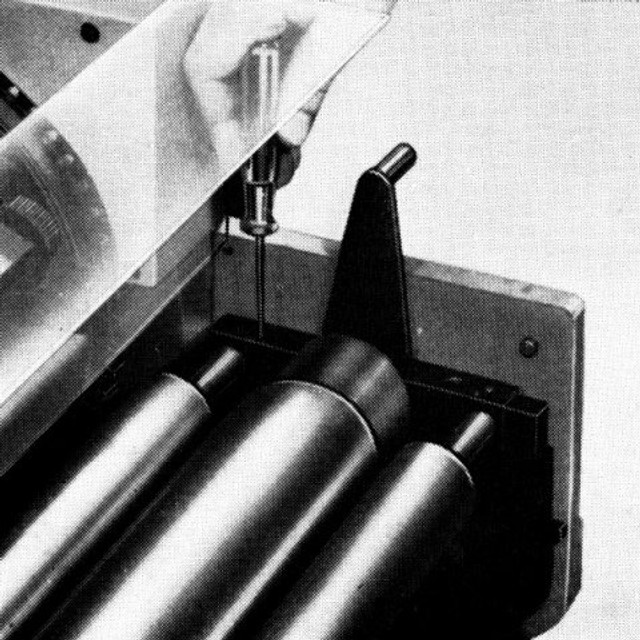

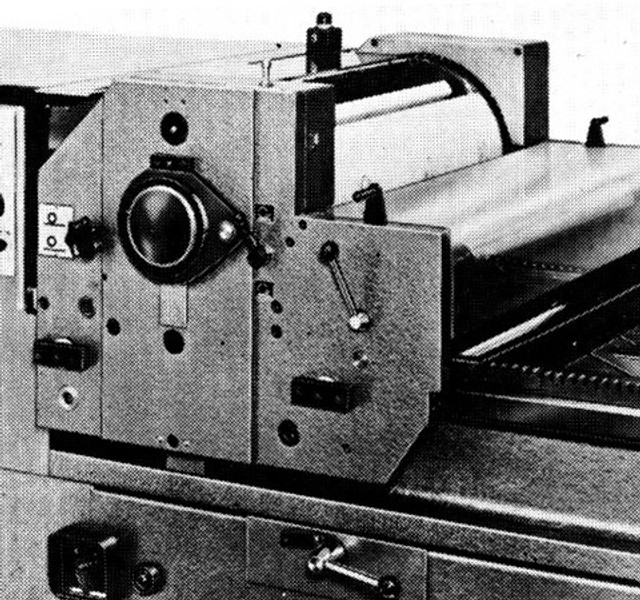

Swing-away ink distribution provides free acess to inking rollers. Inking rollers are mounted on ball bearings. Height adjustment with one single screw. one complete set of inking rollers can be stored on the machine, ready for immediate use. Wedge-type adjustable bed.Bed height adjustment and effective printing height are clearly indicated on a large dial with 1/1000mm (0.0001″) divisions.

Cylinder carriage with ball bearings for precise lateral guidance. Power drive with electronic, stepless speed adjustment. Two-speed power inking: accelerated speed for wash-up and ink distribution, normal speed for printing.

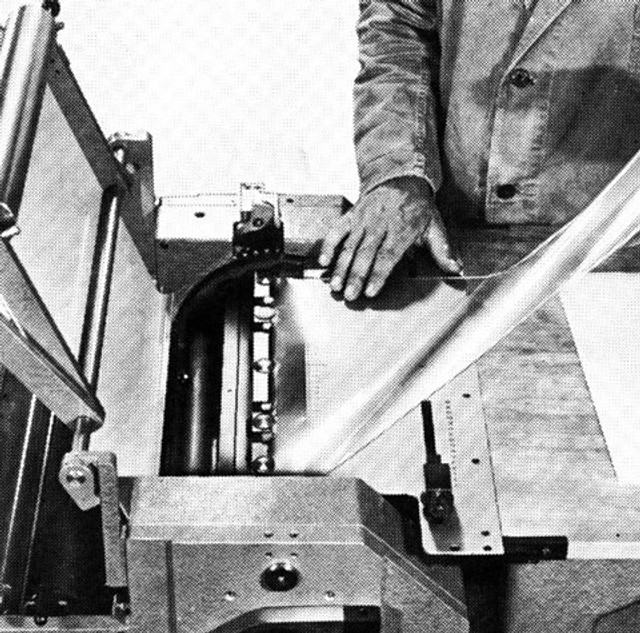

Feed board with swing-away panel serving as a safety device, plus additional safety features for power-driven presses.

Bearer surfaces protected with interchangeable steel bands (available on other later FAG Control models).

Quickspecs

Pressbed size

Paper size

400 × 580 mm

Form size

400 × 560 mm

Press size (l/w/h)

2.3 × 0.86 × 1.2 m

Press weight

Fixed bed: 550kg / adjustable bed: 650kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

Optional equipment

AR / Automatic cylinder return with time adjuster for sheet delivery. (This setting is advisable for orders of Cylinder drive MC.)

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

CP / Special attachment with steel tension roller and .040 inch offset blanket for transparency proofs.

DAS / Split steel rider unit for 2 colour work.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

MC / Cylinder drive with motor and FIXED SPEED SETTING.

MR / Micro adjustable bed movement with clock indicating accurate height in fractions of thousands of an inch. Height is measured directly off table.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

SAF / PMA / Automatic sheet delivery combined with pre lay device for automatic feeding of sheets. Automatic gripper opening at the feed board.

SAM / Safety device for motor-driven machine.

SR / Precision chase

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

TC / Centre side lay for 2 colour work

Number of presses built

~1200

Serial numbers

02.xx.xxx

Built in factory

Avenches, Switzerland

First / last press delivered

1962 / 1991

Price range

20'000 – 30'000CHF

Known presses still in use